RefineX Engine Oil Refiner Product Summary

RefineX Engine Oil Refiner System allows internal combustion engines to run up to 100,000 miles or 6,000 hours without requiring an oil change, applicable for engines running on gasoline, diesel, natural gas, or biofuel. It removes liquid and solid contaminants, protecting oil quality and engine performance. RefineX specializes in advanced filtration technology for internal combustion engines, offering significant cost savings, reduced maintenance, and environmental compliance. The refiner’s advanced system removes contaminants including:

– Liquid impurities (Such as fuel, water, and antifreeze)

– Solid particles (down to 1 micron – such as engine wear metals, dirt, soot and carbon)

– Combustion gases which are generated from the combustion process itself.

This innovative approach virtually eliminates oil change and disposal costs, aligning with EPA emissions standards to deliver a sustainable solution.

“This diagram shows a typical installation and also shows a factory filter only by installing a special bypass adapter on cars and light duty trucks and an alternative adaptation for big diesels the oil is diverted to the mounted pavers for removal of liquids carbon so foot unburnt Fuel and solid particles down to 1 Micron absolute returning contaminant free oil back to your engine and no matter what size your engine is complete refining seven times every hour of operation”

Our Systems

Thermal Breakdown

There are 3 different contaminants that enter the oil in your engine as a result of the combustion process: solids, liquids, and gases.

By-Pass System

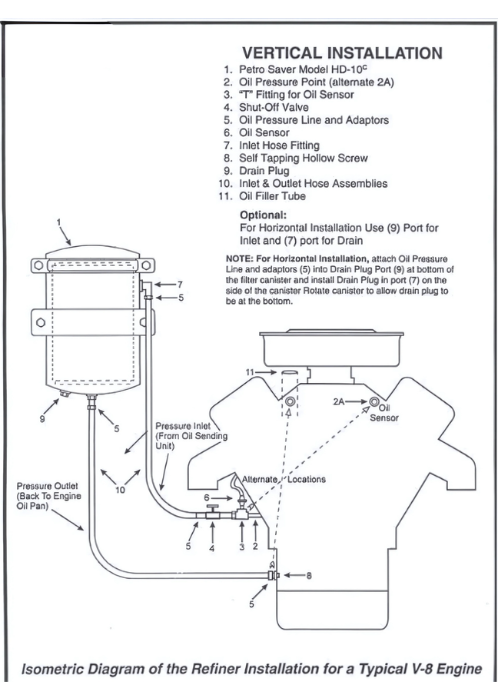

The RefineX operates on the principle of a “By-Pass”. The RefineX Engine Oil Refiner is always connected independently and in parallel with the engine oil full-flow filter. This allows the oil to be pumped from the crankcase through the full-flow engine filter to the oil pressure gallery, then to the bearings without adversely affecting any of the operations. Each refiner is an individual systems approach, which can be engine’s mounted horizontally, vertically, and upside down without affecting operational effectiveness.

Thermal breakdown is when the build-up of solid, liquid, and gaseous contaminants from the combustion process attack and ultimately change the molecular structure of engine oil, leading to an increase in the oil’s viscosity. Thermal breakdown of the oil is when the viscosity of the oil changes, making the oil thicker. Thicker oil takes longer to travel throughout the engine thereby producing an increase in heat and causing damage or wear to the engine. This increase in the oil’s viscosity combined with the engine’s increase in heat causes “Oxidation of the Oil”. The damage that then occurs is due to improper lubrication to certain engine parts caused by oil oxidation.

Engine Wear Reduction

We recognize these challenges the offshore industries face. With our bespoke RefineX Engine Oil Refiner, all water and unburnt fuel is removed from the oil, including all solid and gaseous contaminants, providing an oil with longevity, increasing its lifetime, also ensuring engine wear is reduced to a minimum.